Real PSA simulation module (pyAPEP.simsep)

This module enables ideal PSA simulation using isotherm function and operating conditions.

First, import simsep into Python after installation.

import pyAPEP.simsep as simsep

- Then users need to 10-steps to simulate.

Isotherm selection

Column design

Adsorbent information

Gas property information

Mass transfer information

Thermal information

Boundary condition setting

Initial condition setting

Simulation run

Graph

In next section, detailed steps are explained.

Usage

1. Isotherm selection

Here, we use extended Langmuir isotherm as an example.

First, we need to import some libraries.

import numpy as np

import matplotlib.pyplot as plt

Then, define some parameters of the extended Langmuir isotherm.

# Define parameters of extended Langmuir isotherm

qm1 = 1

qm2 = 0.1

b1 = 0.5

b2 = 0.05

dH1 = 10000 # J/mol

dH2 = 15000 # J/mol

R_gas = 8.3145 # J/mol/K

T_ref = 300 # K

The isotherm is defined as follows.

# Define the isotherm

def extLang(P, T):

P1 = P[0]*np.exp(dH1/R_gas*(1/T-1/T_ref))

P2 = P[1]*np.exp(dH1/R_gas*(1/T-1/T_ref))

deno = 1 + b1*P1 + b2*P2

q1 = qm1*b1*P1 / deno

q2 = qm2*b2*P2 / deno

return q1, q2

2. Column design

# Set the design parameter of a column

col_len = 1 # (m)

cross_sect_area = 0.0314 # (m^2)

num_comp = 2

node = 41 # The number of nodes

# Column definition

Column1 = simsep.column(col_len, cross_sect_area, num_comp, N_node= node)

3. Adsorbent information

voidfrac = 0.4 # Void fraction

rho = 1100 # Solid density (kg/m^2)

Column1.adsorbent_info(extLang, voidfrac, rho_s = rho) # Adsorbent information

print(Column1) # Check

4. Gas property information

Mmol = [0.032, 0.044] # Molecular weights of gases (kg/mol)

visc = [0.01, 0.01] # Viscosities of gases (Pa sec)

Column1.gas_prop_info(Mmol, visc) # Gas property information

print(Column1) # Check

5. Mass transfer information

MTC = [0.05, 0.05] # Mass transfer coefficients

a_surf = 400 # Volumatric specific surface area (m2/m3)

Column1.mass_trans_info(MTC, a_surf) # Mass transfer information

print(Column1) # Check

6. Thermal information

dH_ads = [10000,16000] # Heat of adsorption (J/mol)

Cp_s = 5 # Solid heat capacity (J/kg K)

Cp_g = [10,10] # Gas heat capacity (J/mol K)

h_heat = 10 # Heat transfer coefficient between solid and gas (J/m^2 K s)

Column1.thermal_info(dH_ads, Cp_s, Cp_g, h_heat) # Mass transfer information

print(Column1) # Check

7. Boundary condition setting

P_inlet = 9 # Inlet pressure (bar)

P_outlet = 8.0 # Outlet pressure (bar)

T_feed = 300 # Feed in temperature (K)

y_feed = [0.5,0.5] # Feed composition (mol/mol)

Column1.boundaryC_info(P_outlet, P_inlet, T_feed, y_feed) # Boundary condition

print(Column1) # Check

8. Initial condition setting

P_init = 8*np.ones(node) # Initial pressure (bar)

y_init = [0.2*np.ones(node), 0.8*np.ones(node)] # Gas phase mol fraction (mol/mol)

Tg_init = 300*np.ones(node) # Initial gas temperature (K)

Ts_init = 300*np.ones(node) # Initial solid temperature (K)

P_partial = [P_init*y_init[0], P_init*y_init[1]] # Partial pressure (bar)

q_init = extLang(P_partial, Ts_init) # Solid phase uptake (mol/kg)

Column1.initialC_info(P_init, Tg_init, Ts_init, y_init, q_init) # Initial condition

print(Column1) # Check

9. Simulation run

y, z, t = Column1.run_mamoen(2000, n_sec=10, CPUtime_print=True)

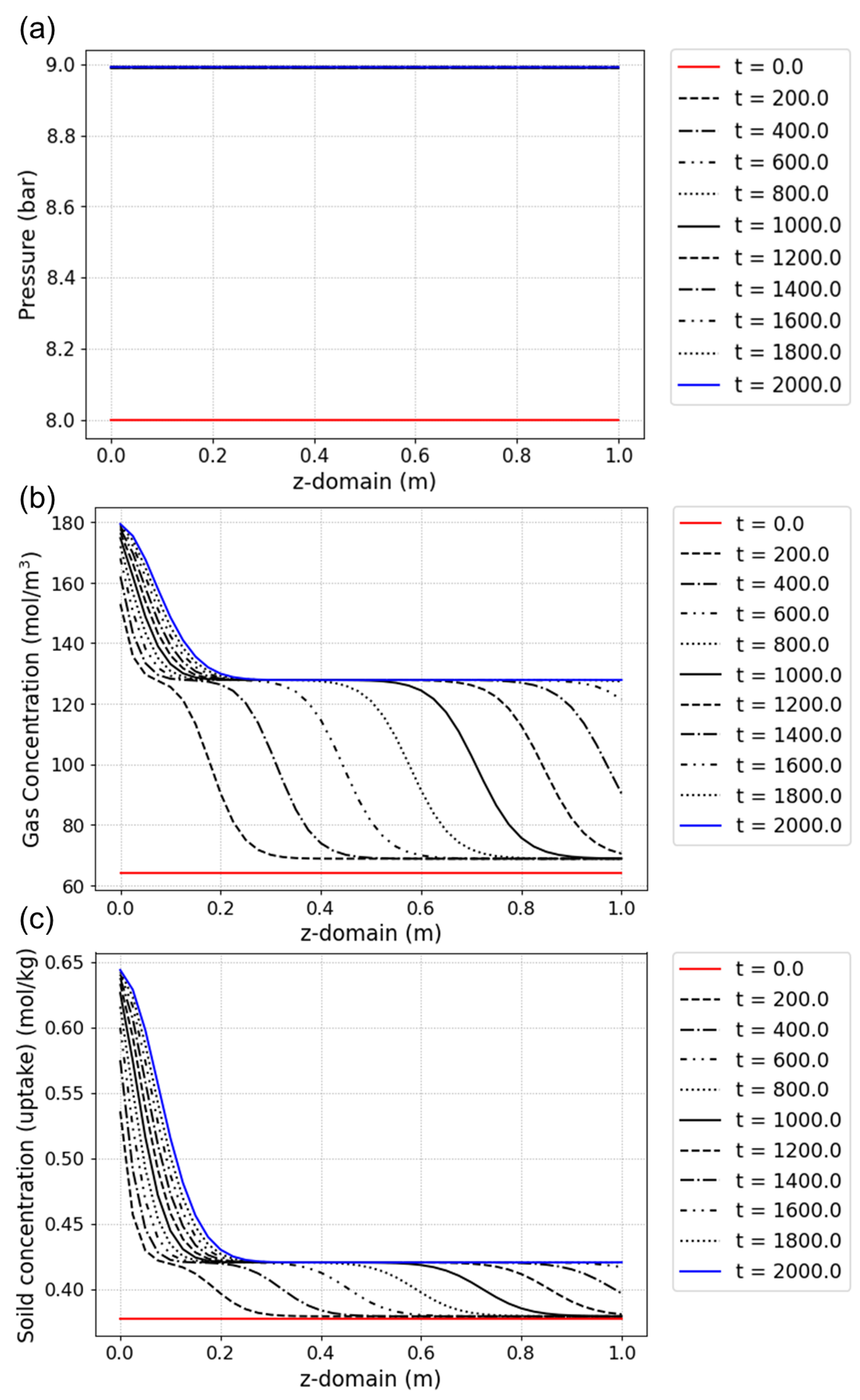

10. Graph

# Simulation result: Pressure according to z-domain

Column1.Graph_P(200,loc = [1.2, 0.9])

# Simulation result: Gas concentration according to z-domain

Column1.Graph(200, 0, yaxis_label=

'Gas Concentration (mol/m$^3$)',loc = [1.2, 0.9])

# Simulation result: Solid concentration according to z-domain

Column1.Graph(200, 2, yaxis_label=

'Soild concentration (uptake) (mol/kg)',loc = [1.2, 0.9])

The results are shown in Fig. (a)–(c)

Class documentation

Real PSA simulation module (pyAPEP.simsep)

- class pyAPEP.simsep.column(L, A_cross, n_component, N_node=11, E_balance=True)[source]

Instantiation. A Column class is for simulating packed bed column or pressure swing adsroption process.

- Parameters:

L – Length of column \((m)\)

A_cross – Cross-sectional area of column \((m^2)\)

n_component – Number of components

N_node – Number of nodes

E_balance – Energy balance inclusion (default = True)

- adsorbent_info(iso_fn, epsi=0.3, D_particle=0.01, rho_s=1000, P_test_range=[0, 10], T_test_range=[273, 373])[source]

Adsorbent information

- Parameters:

iso_fn – Isothem function (Type: n_comp.N array, N array [pressure, temperature])

epsi – Void fraction

D_particle – Particle diameter \((m)\)

rho_s – Solid density \((kg/m^3)\)

P_test_range – Range of pressure for test \((bar)\)

T_test_range – Range of temperature for test \((K)\)

- gas_prop_info(Mass_molar, mu_viscosity)[source]

Gas property information

- Parameters:

Mass_molar – Molar mass \((mol/kg)\)

mu_viscosity – Viscosity \((Pa \cdot s)\)

- mass_trans_info(k_mass_transfer, a_specific_surf, D_dispersion=1e-08)[source]

Mass transfer

- Parameters:

k_mass_transfer – mass transfer coefficient \((s^{-1})\)

a_specific_surf – specific surface area \((m^2/m^3)\)

D_dispersion – dispersion coefficient \((m^2/s)\)

- thermal_info(dH_adsorption, Cp_solid, Cp_gas, h_heat_transfer, k_conduct=0.0001, h_heat_ambient=0.0, T_ambient=298.15)[source]

Thermal information

- Parameters:

dH_adsorption – Heat of adsorption \((J/mol)\)

Cp_solid – Solid heat capacity \((J/kg \cdot K)\)

Cp_gas – Gas heat capacity \((J/mol \cdot K)\)

h_heat_transfer – Heat transfer coefficient between solid and gas \((J/m^2 \cdot K \cdot s)\)

k_conduct – Conductivity of solid phase in axial direction \((W/m \cdot K)\)

h_heat_ambient – Heat transfer coefficient between ambient air and outer surface of the column \((J/m^2 \cdot K \cdot s)\)

T_ambient – Abient temperature \((K)\)

- boundaryC_info(P_outlet, P_inlet, T_inlet, y_inlet, Cv_in=0.1, Cv_out=0.001, Q_inlet=None, assigned_v_option=True, foward_flow_direction=True)[source]

Boundary condition information

- Parameters:

P_outlet – Outlet pressure \((bar)\) [scalar]

P_inlet – Inlet pressure \((bar)\) [scalar]

T_inlet – Inlet temperature \((K)\) [scalar]

y_inlet – Inlet composition \((mol/mol)\) [n_comp array]

Cv_in – Valve constant of inlet side \((m^3/bar \cdot s)\) [scalar]

Cv_out – Valve constant of outlet side \((mol/bar \cdot s)\) [scalar]

Q_inlet – Volumetric flow rate \((m^3/s)\)

assigned_v_option – Assign velocity or not [Boolean]

foward_flow_direction – Flow direction, if this is ‘True’ then the flow direction is foward.

- initialC_info(P_initial, Tg_initial, Ts_initial, y_initial, q_initial)[source]

Initial condition

- Parameters:

P_initial – Initial pressure \((bar)\) [N array]

Tg_initial – Initial gas temperature \((K)\) [N array]

Ts_initial – Initial solid temperature \((K)\) [N array]

y_initial – Gas phase mol fraction \((mol/mol)\) [n_comp N array]

q_initial – Solid phase uptake \((mol/kg)\) [n_comp N array]

- run_mamo(t_max, n_sec=5, CPUtime_print=False)[source]

Run mass & momentum balance equations

- Parameters:

t_max – Maximum time domain value

n_sec – Number of time node per second

CPUtime_print – Print CPU time

- run_mamoen_alt(t_max, n_sec=5, CPUtime_print=False)[source]

Run mass & momentum balance alternative

- Parameters:

t_max – Maximum time domain value

n_sec – Number of time node per second

CPUtime_print – Print CPU time

- run_mamoen(t_max, n_sec=5, CPUtime_print=False)[source]

Run mass & momentum & energy balance

- Parameters:

t_max – Maximum time domain value

n_sec – Number of time node per second

CPUtime_print – Print CPU time

- next_init(change_init=True)[source]

Next initalization

- Parameters:

change_init – Replace inital condition with previous result at final time [boolean]

- Returns:

Previous result at final time (if this is ‘True’, initial conditions are repalced automatically)

- Q_valve(draw_graph=False, y=None)[source]

Q valve

- Parameters:

draw_graph – Show graph [boolean]

y – Simulation result of run_mamo and run_mamoen (if it is ‘None’, this value is from the simulation result automatically)

- Returns:

Volumetric flow rates at Z = 0 and L [time_node array]

- Graph(every_n_sec, index, loc=[1, 1], yaxis_label=None, file_name=None, figsize=[7, 5], dpi=85, y=None)[source]

Making graph

- Parameters:

every_n_sec – Number of points in graph

index – Index determining which graph is to be displayed = 0 - n_comp-1 gas concentration \((mol/m^3)\) / n_comp - 2 n_comp - 1 solid phase uptake \((mol/kg)\) / 2 n_comp gas phase temperature \((K)\) / 2 n_comp + 1 solid phase temeprature

loc – Location of legend

yaxis_label – ylabel of graph

file_name – File name

figsize – Figure size (default [7,5])

dpi – Dot per inch (default 85)

y – Gas phase mol fraction \((mol/mol)\) [n_comp N array]

- Graph_P(every_n_sec, loc=[1, 1], yaxis_label='Pressure (bar)', file_name=None, figsize=[7, 5], dpi=85, y=None)[source]

Making graph of partial pressure

- Parameters:

every_n_sec – Number of points in graph

loc – Location of legend

yaxis_label – ylabel of graph

file_name – File name

figsize – Figure size (default [7,5])

dpi – Dot per inch (default 85)

y – Gas phase mol fraction \((mol/mol)\) [n_comp N array]

- __weakref__

list of weak references to the object (if defined)

- pyAPEP.simsep.step_P_eq_alt1(column1, column2, t_max, n_sec=5, Cv_btw=0.1, valve_select=[1, 1], CPUtime_print=False)[source]

Theory

Mass balance

The mass balance relationship, shown below, is used to describe the pressure swing adsorption process.

where

\(C_{i} =\) Concentration of component i \((mol/m^3)\)

\(t =\) Time \((s)\)

\(D_{dis} =\) Dispersion coefficient \((m^2/s)\)

\(z =\) Length in axial direction \((m)\)

\(\epsilon =\) Void fraction \((m^3/m^3)\)

\(\rho_{s} =\) Density of solid \((kg/m^3)\)

\(q_{i} =\) Uptake of component i \((mol/kg)\)

Momentum balance

In the adsorption process simulation, the pressure drop \(\Delta P\) should be considered to solve the momentum balance along the length of the bed. In 1952, Ergun proposed an equation to consider \(\Delta P\) in a packed bed, and the same equation was used to solve the momentum balance in this package, similar to many previous studies.

The Ergun equation represents the relationship between the pressure drop and resultant fluid flow in packed beds, as shown below. The equation was derived from experimental measurements and theoretical postulates.

where

\(\partial P =\) Pressure drop \((bar)\)

\(L =\) Height of the bed \((m)\)

\(\mu =\) Fluid viscosity \((Pa \cdot s)\)

\(\varepsilon =\) Void space of the bed

\(u =\) Fluid superficial velocity \((m/s)\)

\(d_{P} =\) Particle diameter \((m)\)

\(\rho_{f} =\) Density of Fluid \((kg/m^3)\)

Energy balance

The energy balance, shown below, is also used to describe the pressure swing adsorption process.

The overall energy balance under the boundary condition for the gas phase:

The overall energy balance under the boundary condition for the solid phase:

where

\(C =\) Concentration \((mol/m^3)\)

\(C_{p, g} =\) Gas heat capacity \((J/mol \cdot K)\)

\(T_{g} =\) Gas temperature \((K)\)

\(t =\) Time \((s)\)

\(u =\) Velocity \((m/s)\)

\(z =\) Length in axial direction \((m)\)

\(h =\) Enthalpy \((J/m^2 \cdot K \cdot s)\)

\(\varepsilon =\) Void fraction \((m^3/m^3)\)

\(a_{surf} =\) Interfacial area concentration \((m^2/m^3)\)

\(T_{s} =\) Solid temperature \((K)\)

\(\rho_{s} =\) Density of solid \((kg/m^3)\)

\(q_{i} =\) Uptake of component i \((mol/kg)\)